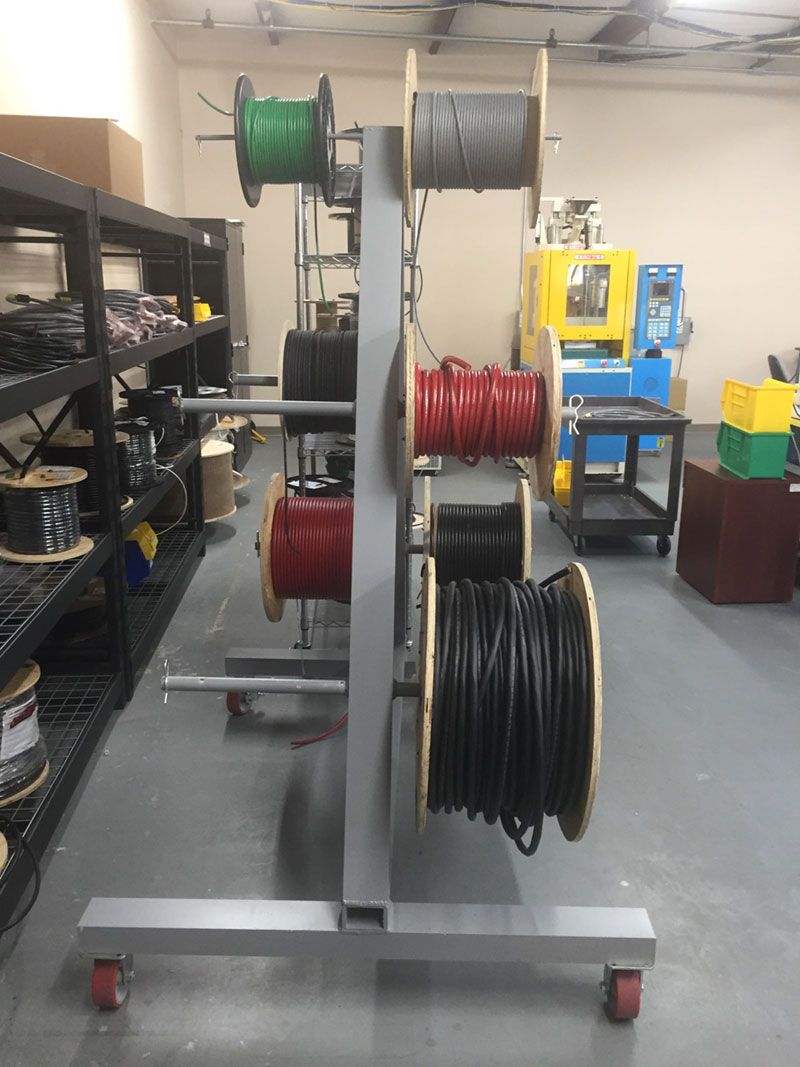

Design and manufacturing of cable storage system for defense contractor teammate

AC, Inc. designed and manufactured a cable storage system for a defense contractor teammate. The customer came to AC, Inc. with a firm visual impression of what they wanted, along with load, strength, stability and footprint requirements. The problem was that they didn’t have drawings to bring the project to fruition.

Fabrication and use of 3D models to generate drawings

Using state-of-the-art CAD/CAM software, AC, Inc. was able to take the visual impression and design requirements presented by the customer and generate 3D models. Those models were then evaluated to show that all the weight, strength and stability requirements were exceeded. Then 3D models were then used to seamlessly generate two dimensional drawings and machine programs that allowed the manufacturing process to be completed with minimum time, minimum effort and maximum cost savings.

Test and evaluation using 3D models

Using CAD/CAM or other engineering software, AC, Inc. is able to generate new 3D models or work with existing models by importing and translating to generate drawings, update and improve existing drawings, perform testing and evaluation data or incorporate alternative manufacturing strategies.